Offline solutions

Offline solutions

Office software for bending programming. Allows you to perform both the design of the product and the check in offline mode, thus not interfere with the normal production of the plant.

Complete suite that faces and solves all the bending management problems. Developed on the IDEA PC

platform, provides multiple machines management, parts import in DXF, IGES and Step format and a careful

selection of printing reports.

Nowadays, modern sheet production is inconcievable without a high-performance software. A highly efficient control alghoritm optimizes the machine cycle, reducing the time required for the set-up and ensures a consistent high quality.

IDEABEND is a complete suite which faces and solves all the bending management issues. It allows to carry out both the product design and the verification in offline conditions, without interfering with the production.

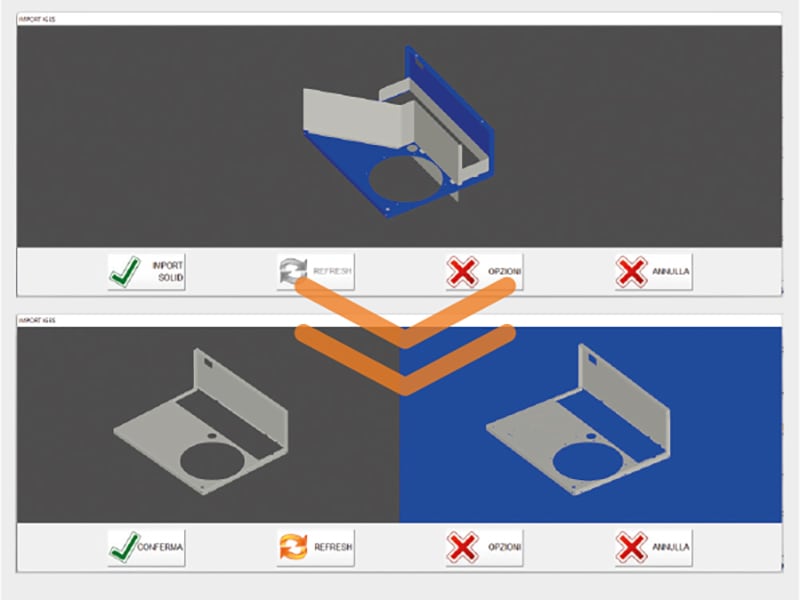

Parts import can be done in more manner:

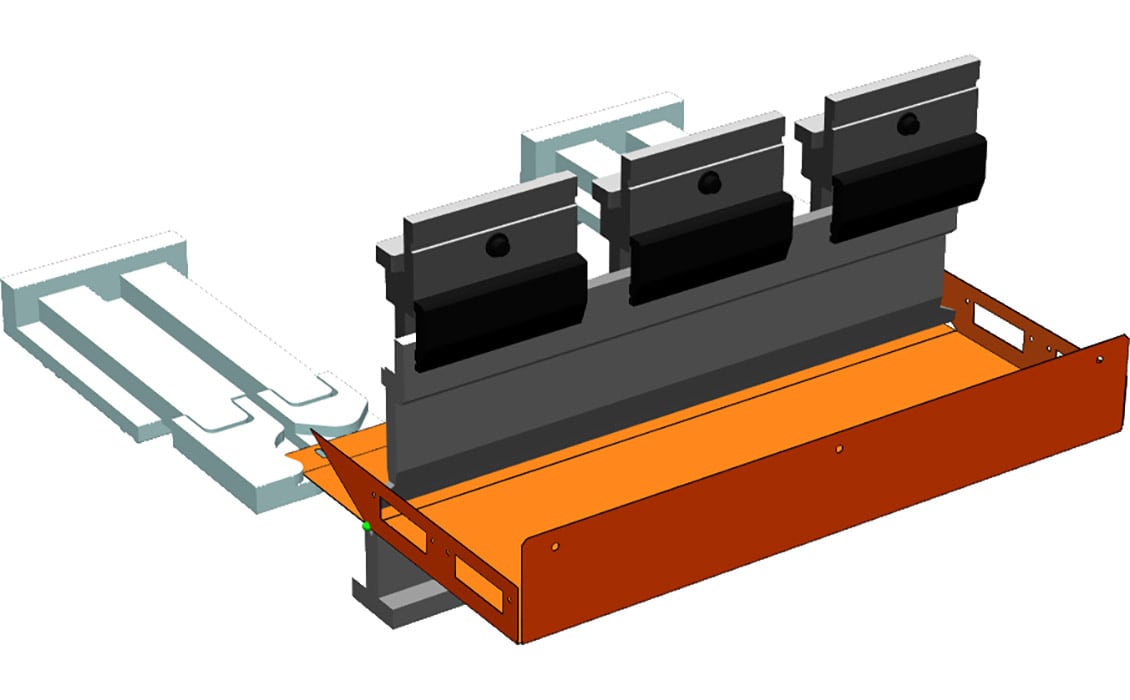

Assembly management also allows you to import medium to high complexity 3D drawings, in IGES and STEP formats, to be analyzed and decomposed in all constituent parts.

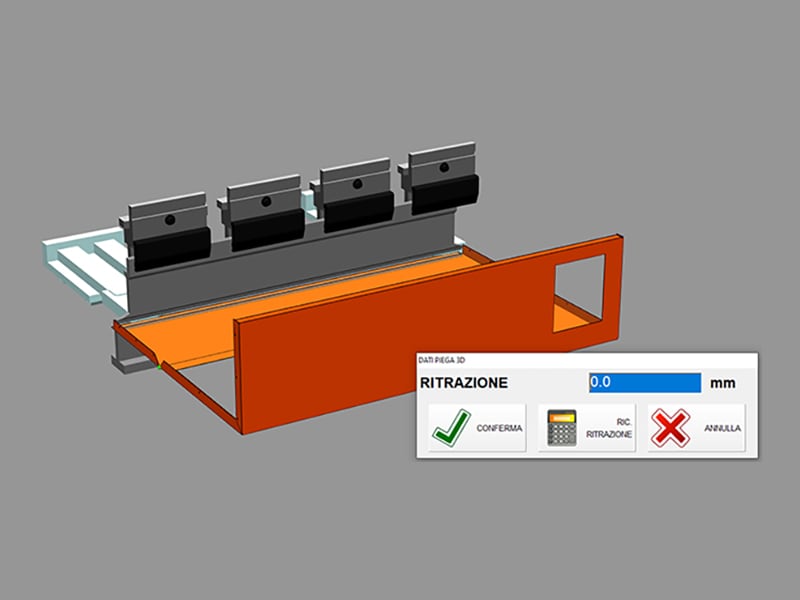

The software is able to analyze the imported piece and automatically identify the most suitable equipment and the best bending sequence.

Thanks to the 3D view it is possible to scroll the sequence manually and view the results obtained.

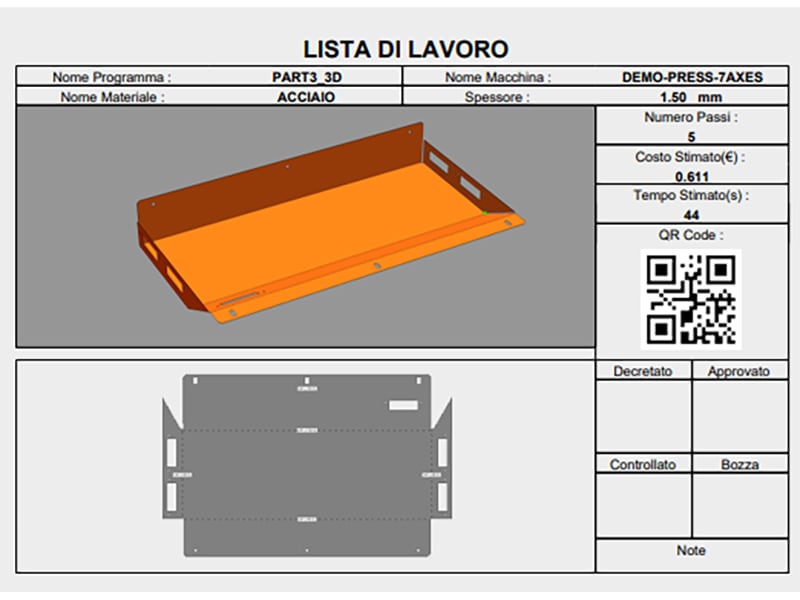

IDEABEND allows you to generate, for each program, the PDF Report which summarizes the main information obtained from the study of the piece, including the tooling, the bending sequence, the time estimate, the

QR Code associated with the program and many others useful data for the operator.

The Industry 4.0 package includes all the functions that allow you to manage the scheduling of programs directly from the office, monitor the progress of production and view the status of the machine in real time.