CNC

CNCThe new ROCK22 DUAL offers top level efficiency in press brakes programming and control. The winning Made in Italy design and the high quality of all the construction details, guarantee prestigious performances and a long product life.

In the second virtual monitor area, you can view useful documents such as images, videos, PDFs or live webcam, which can also be loaded from your mobile device, and visible and accessible during production. What is traditionally used as a paper support (drawings of the piece, specific details of the tooling or production sequence) becomes multimedia content available on the upper screen.

It’s Industry 4.0 Ready thanks to the production and maintenance management and support for remote programming and supervision. Machine status monitoring through cloud reporting and system integration into a smart factory, through support for the MTConnect industrial communication standard and IoT support through MQTT protocol.

| Cpu card | ITX module, low power consumption, Quad Core Intel 2.3GHz |

|---|---|

| RAM | DDR3 4Gb |

| Supply | 24Vdc |

| Monitor | Colours LCD TFT, Capacitive Touch-screen |

| Hard disk | M.2 SSD 128 GByte |

| Net Card | 2 Gigabit Ethernet RJ-45 |

| Net Card | 2 Gigabit Ethernet RJ-45. |

| Power | 36W (1.5A - 24Vdc) |

| Model | Software | Axis number |

|---|---|---|

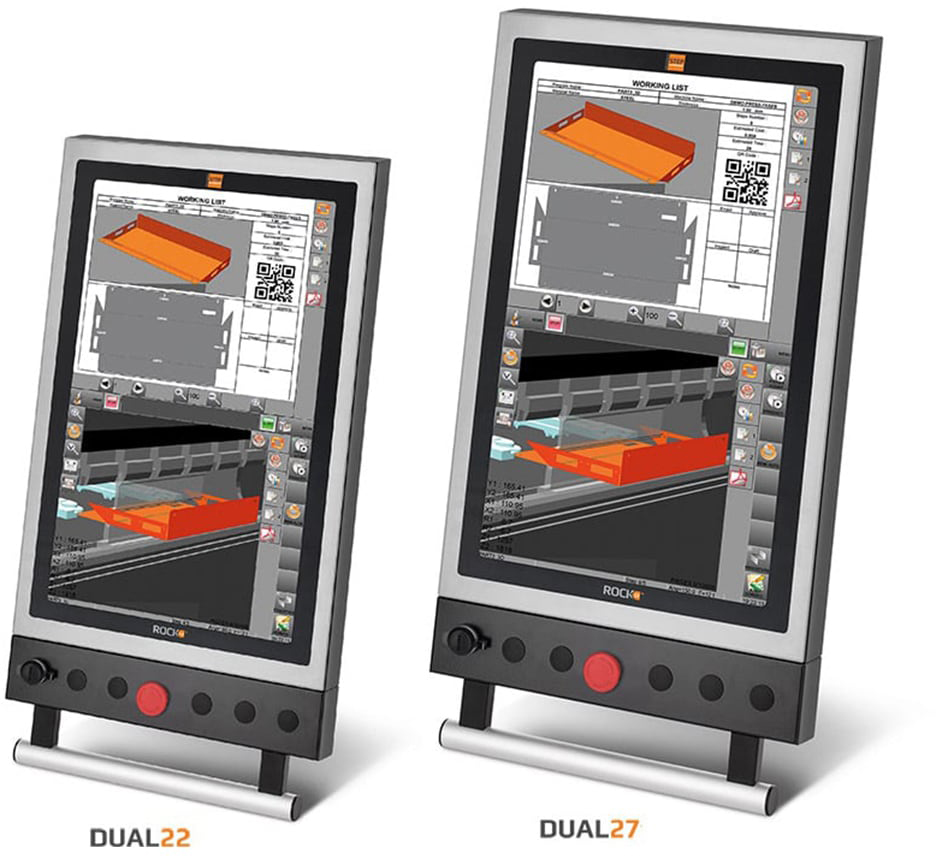

| DUAL 22 | Standard 3D | 12 |

| DUAL 22+ | Advanced 3D | 12 |

| DUAL 27 | Standard 3D | 12 |

| DUAL 27+ | Advanced 3D | 12 |

| Standard 3D | 3D editor and simulation, DXF parts import |

| Advanced 3D | Add to Standard 3D the IGES/STEP parts import |

Motion is the modular units that STEP designed to interface and control all types of Press brakes: hydraulics, electrical and hybrids. It’s equipped with a PLC logic with a lot of inputs/outputs. The numerical control, connected through Can Bus or USB interface to one or more Motion modules, is able to completely manage the machine.

eMotion is the new modular units that STEP designed like evolution of the traditional Motion line, to interface and control all types of Press brakes: hydraulics, electrical and hybrids.

It extends the traditional functions with the addition of the support of the EtherCAT protocol for the interface to the drives, of the interface to the absolute linear scales and provides for an Ethernet communication with the CNC.

STEP has designed a new system of bending assisted by a multicolor LED bar. The system, named LED Bend Guiding System, is used to describe a lot of conditions, that helps the operator to interact quickly with the machine. Productivity and aesthetics are combined in an efficient manner.

STEP Automation offer offline CAD/CAM for all applications developed.

All software, in addition to allowing a quick definition and simulation of part programs, are equipped with functionality for Industry 4.0 interconnection.